News Story

Looking for a strong adhesive? Check out Heat Activated Film (HAF) adhesives!

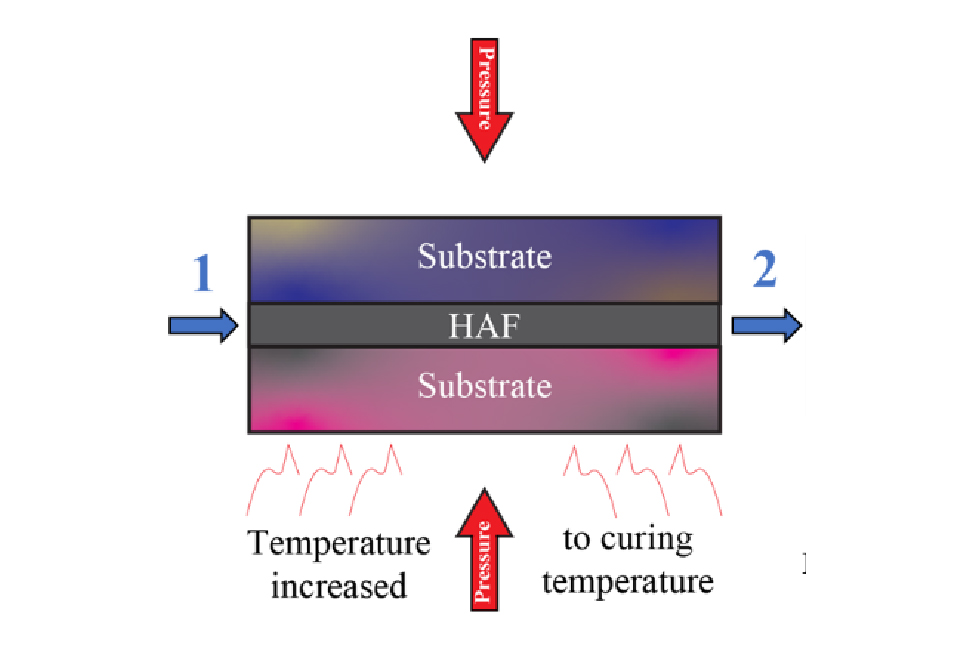

Heat Activated Film, or HAF, adhesives are a great alternative to conventional adhesives or mechanical linkages in securing components in electronics. Unlike other conventional adhesives, HAF is not sticky at room temperature. But as the name suggests, it is reactive to temperature as it can be activated at elevated temperatures and pressures. To bond two surfaces, HAF needs to be heated to and maintained at its curing temperature for a specified period. As the HAF cures, the bonding takes place. Once fully cured, crosslinking occurs shortly after, giving HAF its excellent mechanical performance.

HAFs are very well suited to bonding materials that are inherently difficult to bond. They are typically used in the bonding of fabric and leather, magnets to rotors, and any kind of friction materials. HAFs typically have a very high bonding strength once cured and are resistant to oils, solvents, and UV radiation. As they are generally thermoset polymers, they are less likely to debond at higher temperatures.

So, you may be thinking HAF sounds like an ideal adhesive! Unfortunately, you must consider the potential issues of using HAF:

- The phase transition temperature of HAF falls within the operating temperature range of most devices.

- As with any thermoset material, thermoset HAFs are susceptible to premature curing at any point between manufacturing, logistics, and storage. Premature curing may alter the expected properties of these materials significantly and unpredictably, making the HAF unreliable.

- Excessive deformation and debonding may be observed at stress concentration sites.

What can be done to maximize the effectiveness of HAF despite these issues? Of the three factors above, the effect of premature curing is the most viable to control. To control premature curing, the degree of cure of the material must be quantified.

Once the degree of cure of HAF is understood, it allows us to greatly enhance the performance of HAF. If the degree of cure can be measured, it becomes possible to screen out excessive premature curing. It also allows us to define the optimal storage and handling conditions to minimize premature curing. While HAF may bring up potential issues and precautions, it proves to be a viable alternative to conventional electronic adhesives.

For more information, contact Prof. Abhijit Dasgupta.

Published March 6, 2020