News Story

Part Assessment Based on Side Channel Testing - New Air Force STTR Project on Quantifiable Assurance for Mission-Critical Microelectronics

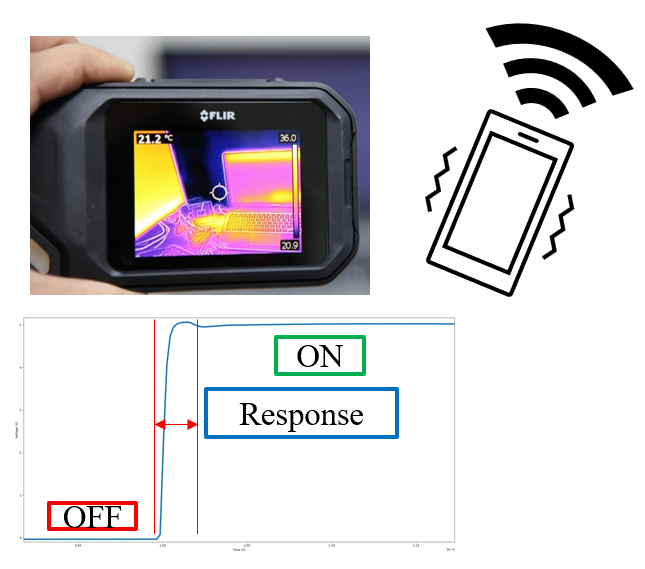

Examples of Side-Channel - A thermal image, electromagnetic emission, and electrical signal response

Side channels are indirect sources of information that originate from a device and contain information about its physical state or function. While side channels have been utilized in the field of cryptography and security, their potential use in the fields of quality and reliability assessment remains unexplored. CALCE is pioneering cutting-edge research on this test method, which holds great potential for identifying electronic products that deviate from acceptable quality and reliability characteristics. Side channel testing is non-destructive and can be performed in a matter of seconds, potentially requiring connections only to power and ground terminations. CALCE is partnering with commercial companies to aid in the development of the test method so that it can be readily implemented using affordable and commercially available equipment.

This Air Force Small Business Technology Transfer (STTR) project propels this work forward in collaboration with Chiplytics. Chiplytics manufactures Power Spectrum Analysis (PSA), which is a fast, non-invasive electrical testing technique licensed from Sandia National Laboratories that captures a unique multi-pin frequency response to reveal differences between components. CALCE's work in this project is expected to contribute to the identification of potential applications of the methods and tools outside of authentication, including the assessment of aging in microelectronic devices.

This Air Force Small Business Technology Transfer (STTR) project propels this work forward in collaboration with Chiplytics. Chiplytics manufactures Power Spectrum Analysis (PSA), which is a fast, non-invasive electrical testing technique licensed from Sandia National Laboratories that captures a unique multi-pin frequency response to reveal differences between components. CALCE's work in this project is expected to contribute to the identification of potential applications of the methods and tools outside of authentication, including the assessment of aging in microelectronic devices.

CALCE will perform testing and evaluation of components using the PSA system to evaluate and improve the technology and the underlying algorithms. When fully funded, the CALCE team will perform the following tasks:

- Identify the components to test for evaluating the capabilities of the PSA system, the prevalence of counterfeiting by part type (e.g., analog, programmable logic, microprocessor, and memory ICs), and the diversity of part types.

- Collect data on components using both the commercial PSA system and benchtop test and measurement equipment.

- Evaluate the classification accuracy of the commercial PSA system in detecting counterfeit or surrogate counterfeit devices. (Surrogate devices can include two sets of similar parts with different operational ratings or different manufacturers.)

- Compare the sensitivity and classification accuracy of the commercial PSA system with that of benchtop test and measurement equipment.

- Evaluate feature extraction and classification algorithms and develop requirements for increasing classification accuracy.

Published June 14, 2024