Defect Description

Voids present in solder joints that can lead to local stress concentration and crack initiation upon the exposure to environmental stresses such as temperature cycling and vibration.

Defect Formation Process(s)

Solder joint voiding has been extensively studied and formation of some types of voids are included here. Reliability of a voided solder joint depends on dimensions, locations of the voids and anticipated field environment, working time frame of the product.

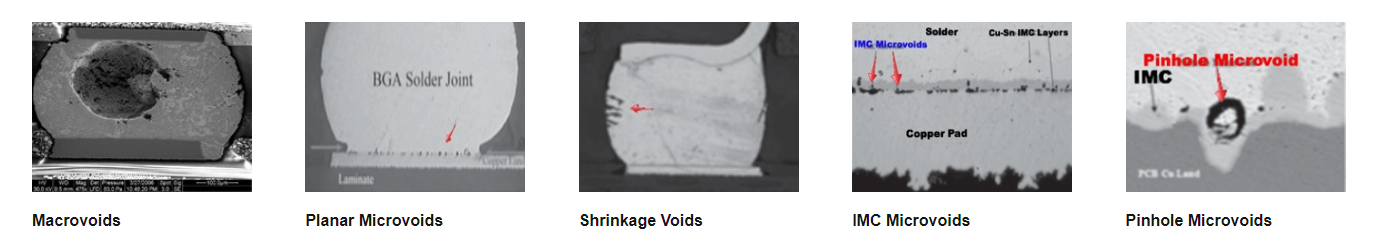

Macrovoids

Generated by evolution of volatile compounds from the ingredients (flux, binders, solvents) of the solder paste, and from the gaseous reduction of metallic oxides on the surfaces being soldered to, during the soldering process [1]

Planar Microvoids

Generated by interaction of several factors: thick (>25 -inch) Ag coating soldered at low-temperature, volatilization of excessive codeposited organics during ImAg deposition, trapped gaseous voids, oxidation of the surface finish on the pads, some form of intermetallic reaction displacement [1]

Shrinkage Voids

Caused by the shrinkage during solidification [1]

IMC Microvoids

Form after aging at high temperature or during temperature cycling of solder joints, Kirkendall voiding mechanism can be one of the root cause of this type of voids [1]

Pinhole Microvoids

Caused by entrapped PCB fabrication chemicals within existing pinholes that volatilize during the reflow soldering process [1]

|

List of Tests to Precipitate this Defect |

Failure Acceleration |

Likelihood to Precipitate this Defect (condition) |

Failure Mechanism(s) |

|

Thermal Shock |

• Cyclic thermal mechanical stress accelerates crack initiation or growth around voids where stress concentration is higher • Thermal mechanical stress causes fracture of the solder joint around the voids where local stress concentration is high |

✔ |

Thermal Faitgue Thermal mechanical Oberstress |

|

Random Vibration (RS/ED) |

• Random Vibration accelerates fatigue cracking of the solder joints around voids where stress concentration is higher • Random Vibration can cause fracture of the solder joints around voids where stress concentration is higher |

✔/✇ |

Mechanical Fatigue Mechanical Overstress |

|

Combined Environment |

• Combination of Thermal Shock and Random Vibration |

✔ |

Combination of Thermal Shock and Random Vibration |

|

Bend Test |

• Bending can cause fracture of the solder joints around voids where stress concentration is higher |

✇ |

Mechanical Overstress |

References

[1] Aspandiar, Raiyo F., “Voids in Solder Joints.” SMTA Journal, vol. 19, issue 4, pp. 28-36, 2006.

Permission for pictures

[2] Aspandiar, Raiyo F., “Voids in Solder Joints.” SMTA Journal, vol. 19, issue 4, pp. 28-36, 2006.

Top