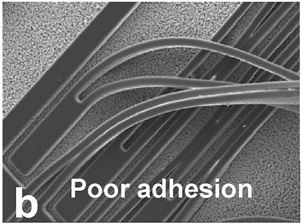

Defect Description

The adhesion between the surface trace and the plated surface is weak due to manufacture variations and is prone to separation or peeling upon the exposure to environmental stresses.

Defect Formation Process(s)

One possible cause for this defect can be contamination. Contaminants such as grease, dust, fibers, hair, skin flakes can result in poor adhesion between the copper foil and the plated surface [1].

|

List of Tests to Precipitate this Defect |

Failure Acceleration |

Likihood to Precipitate Defect (condition) |

Failure Mechanism(s) |

|

|

Thermal Shock |

• Thermal shock accelerates separation of the interface due to CTE mismatch. • Thermal mechanical stress can cause fatigue cracking of thin copper trace that is not plated properly on the surface • Thermal mechanical stress can cause fracture of the thin copper trace that is not plated properly on the surface |

✔ |

Thermal Fatigue Thermal Mechanical Overstress |

|

|

Random Vibration (RS/ED) |

• Random Vibration accelerates separation of the poorly bonded interface due to vibration-induced fatigue • Random Vibration causes fatigue cracking of the copper trace that is not plated properly on the surface • Random vibration can cause fracture of the thin copper trace that is not plated properly on the surface |

✔/✇ |

✔/✇ |

Mechanical Fatigue Mechanical Overstress |

|

Combined Environment |

• Combination of Thermal Shock and Random Vibration |

✔ |

Combination of Thermal Shock and Random Vibration | |

|

Bend Test |

• Bending can separate the poorly bonded interface by mechanical overstress • Bneding can cause fracture of the thin copper trace that is not plated properly on the surface |

✇ (Defect at a location with significant strain due to bending) |

Mechanical Overstress |

[2]

[2]

References

Permission for pictures

[2] Horiuchi, Michio, Tomoo Yamasaki, and Yuichiro Shimizu. "Metallization technologies on a smooth resin surface for the next generation of flip chip packaging." Transactions of The Japan Institute of Electronics Packaging 3.1 (2010): 110-115.

Top