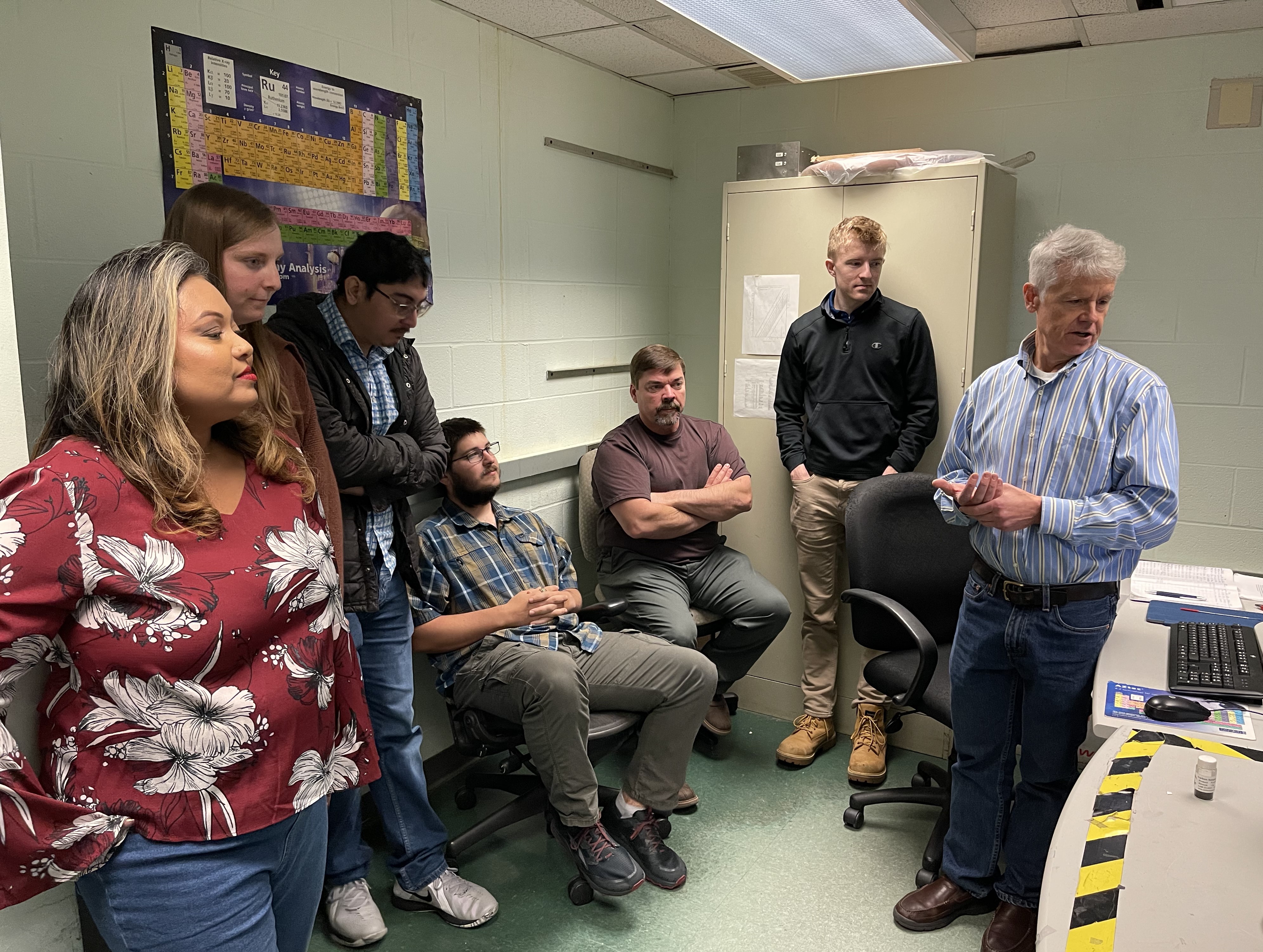

The Course was held from November 15 - 18, 2022 at the University of Maryland, College Park. The course was capped at 16 which was fully subscribed within 3 days of the registration opening and it received a turnout from multinational companies like Sandia National Laboratories, Honeywell FM&T, Amazon Web Services, Crane A & E, Tektronix, US Navy, and Elbit America. If you are interested in attending failure analysis courses in the future, please contact Dr. Michael Osterman.

This intensive 4-day course covered specimen preparation and materials analysis techniques applicable to electronic assemblies, components, and devices. The course consisted of a combination of classroom instruction, demonstrations, and hands-on laboratory training. Lecture topics included physics-of-failure root cause analysis, guidelines for selecting analytical tools, practical instruction on laboratory techniques, and case studies drawn from CALCE’s research. The laboratory portion of the course included demonstrations and step-by-step hands-on sample preparation using metallographic techniques on failure analysis and inspection equipment. In addition, a number of essential non-destructive and destructive analysis techniques were demonstrated.

This intensive 4-day course covered specimen preparation and materials analysis techniques applicable to electronic assemblies, components, and devices. The course consisted of a combination of classroom instruction, demonstrations, and hands-on laboratory training. Lecture topics included physics-of-failure root cause analysis, guidelines for selecting analytical tools, practical instruction on laboratory techniques, and case studies drawn from CALCE’s research. The laboratory portion of the course included demonstrations and step-by-step hands-on sample preparation using metallographic techniques on failure analysis and inspection equipment. In addition, a number of essential non-destructive and destructive analysis techniques were demonstrated.

An attendee from Honeywell, Mr. Olugbenga Kayode said "This course has been one of the best experiences of my professional career. The curiosity to do a deep dive into the root cause failure analysis of electronic components is exciting and requires vigilance and dedication in the study of failure analysis, also a good knowledge about current industrial advancements. An excellent experience and I will never forget such dedicated staff and graduate assistants. Thank You!."

An attendee from Honeywell, Mr. Olugbenga Kayode said "This course has been one of the best experiences of my professional career. The curiosity to do a deep dive into the root cause failure analysis of electronic components is exciting and requires vigilance and dedication in the study of failure analysis, also a good knowledge about current industrial advancements. An excellent experience and I will never forget such dedicated staff and graduate assistants. Thank You!."

Course Instructors

Lead Instructor

Dr. Michael Azarian | mazarian@umd.edu

Dr. Michael Azarian | mazarian@umd.edu

Dr. Michael H. Azarian is a Research Scientist at CALCE. He holds a Masters and Ph.D. in Materials Science and Engineering from Carnegie Mellon University, and a Bachelors degree in Chemical Engineering from Princeton University. His research is focused on the analysis, detection, prediction, and prevention of failures in electronic and electromechanical products. He has over 150 publications and 6 U.S. patents involving electronic packaging, component reliability, prognostics and health management, and tribology. Dr. Azarian is chairman of the SAE G-19A standards committee on the detection of counterfeit parts, which is responsible for the AS6171 and AS6810 family of standards, and chair of the standards committee for IEEE 1624 on organizational reliability capability.

Co-Instructor

Dr. Michael Osterman | osterman@umd.edu

Dr. Michael Osterman is a Research Scientist and the director of the CALCE Electronic Products and System Consortium at the University of Maryland. He holds a Ph.D. from the University of Maryland and he currently heads the development of simulation-assisted reliability assessment software for CALCE and simulation approaches for estimating the time to failure of electronic hardware under test and field conditions. Dr. Osterman served as a subject matter expert on phases I and II of the Lead-free Manhattan Project sponsored by the Office of Naval Research in conjunction with the Joint Defense Manufacturing Technical Panel (JDMTP).

Co-Instructor

Dr. Robert Utter | rgutter@umd.edu

Dr. Robert Utter | rgutter@umd.edu

Dr. Robert Utter is a member of the CALCE technical staff. Dr. Utter brings a wealth of experience in electronic product development ranging from material analysis to software development. Dr. Utter is a chemist with a doctorate from the University of Texas. He has held positions in contract manufacturing at Kimball International and material analysis at Alliant Techsystems Operations. His expertise includes in-depth knowledge of spectroscopy and microscopy essential for understanding electronic product reliability.

Contact

Dr. Michael Osterman

301-405-8023 | osterman@umd.edu

University of Maryland

College Park, MD 20742

For any course-related and registration queries, please contact Dr. Michael Osterman

Top