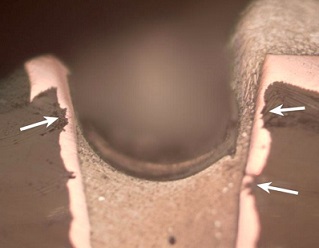

Defect Description

Protrusion of glass fiber in the board laminate into PTH walls that affects PTH plating thickness and can contribute to PTH cracks [1]

Defect Formation Process(s)

Possible causes for this defect can be process control variability during hole drilling, hole preparation or application of flash copper [1]

|

List of Tests to Precipitate this Defect |

Failure Acceleration |

Likelihood to Precipitate this Defect (condition) |

Failure Mechanism(s) |

|

Thermal Shock |

• Cyclic thermal mechanical stress accelerates crack initiation or crack growth at the protrusions where local stress concentration is high • Thermal mechanical stress causes fracture of the copper plating at the protrusions where local stress concentration is high |

✔ |

Thermal Fatigue Thermal Mechanical Overstress |

|

Random Vibration (RS/ED) |

• Random Vibration accelerates crack initiation or crack growth at the protrusions where local stress concentration is high • Vibration causes fracture of the copper plating at the protrusions where local stress concentration is high |

✔/✇ |

Mechanical Fatigue Mechanical Overstress |

|

Combined Environment |

• Combination of Thermal Shock and Random Vibration |

✔ |

Combination of Thermal Shock and Random Vibration |

|

Bend Test |

• Bending can cause fracture of the copper plating at the protrusions where local stress concentration is high |

✇ (Defect at a location with significant strain due to bending) |

Mechanical Overstress |

[2]

[2]

References

[1] Tulkoff C., Hillman C., “Reliable plated through via design and fabrication.” DFR Solutions

Permission for pictures

[2] Tulkoff C., Hillman C., “Reliable plated through via design and fabrication.” DFR Solutions

Top