Terms of Use

Mission

Data Description

Cylindrical Cells

INR 18650-20R Battery

| Battery (Parameters) | Specifications (Value) |

| Capacity Rating | 2000 mAh |

| Cell Chemistry | LNMC/Graphite |

| Weight (w/o safety circuit) | 45 g |

| Dimensions (mm) | 18.33 mm ± 0.07 mm |

| Length | 64.85 mm ± 0.15 mm |

| Special Notes | Tab length not included in the dimensions |

Data and Test Description

Battery state of charge (SOC) estimation is a crucial function of battery management systems (BMSs), since accurate estimated SOC is critical to ensure the safety and reliability of electric vehicles. A widely used technique for SOC estimation is based on online inference of battery open circuit voltage (OCV). Low-current OCV and Incremental-current OCV tests are two common methods to observe the OCV-SOC relationship, which is an important element of the SOC estimation technique.

We conducted an experiment where these two OCV tests are run at three different temperatures and based on which, two SOC estimators are compared and evaluated in terms of tracking accuracy, convergence time, and robustness. In addition, four dynamic tests are presented, one for estimator parameter identification and the other three for estimator performance evaluation.

The comparison results show that estimator 2(based on the incremental OCV test) has higher tracking accuracy and is more robust against varied loading conditions and different initial values of SOC than estimator 1 (based on the lowcurrent OCV test) with regard to ambient temperature. Therefore, the incremental OCV test is recommended for predetermining the OCV-SOCs for battery SOC online estimation in BMSs. The data for the tests performed is available below for download.

Low Current OCV

The Low-current OCV test used a small current (e.g. C/20, C/25) to charge and discharge the battery so that the corresponding terminal voltage is an approximation of OCV. The test execution steps are:

- Charge battery fully to 100% SOC

- Now discharge using a negative pulse current relaxation duration at every 10% SOC

- Charge again following the same routine but with a positive pulse current

-

Apply Averaging and Linear Interpolation step to obtain the OCV-SOC

curve at 0°C, 25°C and 45°C.

| Sample 1: | ||||

| Sample 2: |

Incremental Current OCV

The Incremental OCV test consisted of many SOC intervals and rest periods after which the OCV with the corresponding SOC were observed. Additional data points for the OCV curve were obtained within the SOC intervals using interpolation methods. The test execution steps are:

- Charge battery to cut-off voltage of 4.2V at constant current of 1C-rate

- Charge at constant voltage until its current is reduced to 0.01C

- Now Discharge at constant rate of C/20 until the voltage drops to 2.5V

- Fully Charge at constant rate of C/20 to 4.2V

- Average voltage of charging and discharging process recorded as OCV at 0°C, 25°C and 45°C.

| Sample 1: | ||||

| Sample 2: |

Dynamic Test Profile

This test consists of different dynamic current profiles like Dynamic stress test DST , Federal Urban Driving Schedule FUDS, US06 Highway Driving Schedule and Beijing Dynamic Stress Test BJDST.

All tests were performed for 80% battery level and 50% battery level at 0°C, 25°C and 45°C.

| DST: | |||

| FUDS: | |||

| US06: | |||

| BJDST: |

The above data files have been referenced in:

[1] Influence of different open circuit voltage tests on state of charge online estimation for lithium-ion batteries.

Fangdan Zheng, Yinjiao Xing, Jiuchun Jiang, Bingxiang Sun, Jonghoon Kim, Michael Pecht, Applied Energy, 183, pp.513–525, 2016.

[2] State of Charge Estimation of Lithium-Ion Batteries Using the Open-Circuit Voltage at Various Ambient Temperatures.

Yinjiao Xing, Wei He, Michael Pecht and Kwok Leung Tsui, Applied Energy, 113, pp.106-115, 2014.

[3] State of Charge Estimation for Li-Ion Batteries Using Neural Network Modeling and Unscented Kalman Filter-based Error Cancellation.

Wei He, Nicholas Williard, Chaochao Chen, Michael Pecht , International Journal of Electrical Power & Energy Systems, 62, pp.783-791, 2014.

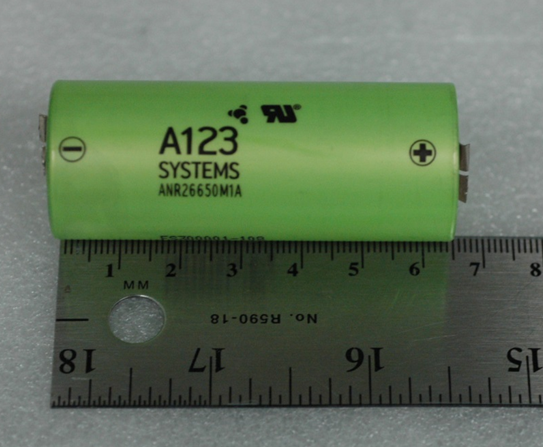

A123 Battery

| Battery (Parameters) | Specifications (Value) |

| Capacity Rating | 2230 mAh |

| Cell Chemistry | LiFePO4 |

| Weight (w/o safety circuit) | 76 g |

| Dimensions | 25.4 mm |

| Length | 65 mm |

| Special Notes | Tab length not included in dimensions |

Data and Test Description

Ambient temperature is a significant factor that influences the accuracy of battery SOC estimation, critical for remaining driving range prediction of electric vehicles (EVs) and optimal charge/discharge control of batteries. A widely used method to estimate SOC is open-circuit voltage (OCV). However, the fact that the OCV–SOC is dependent on ambient temperature and can result in errors in battery SOC estimation. To address this problem we conducted an experiment with A123 cell wherein we used two dynamic tests: Dynamic stress test (DST) and the Federal urban driving schedule(FUDS), former to identify the model parameters while later to validate the performance of the SOC estimation. The test was performed as listed below:

- Run two dynamic charge discharge test: DST and FUDS for temperature ranging from 0°C to 50°C with interval of 10°C.

- Run Low Current OCV-SOC test for temperature ranging from 0°C to 50°C with interval of 10°C.

- Develop an estimation method for OCV-SOC using model created from DST test results.

- Validate the estimation method with FUDS test results.

The data used in the experiment is available below for download.

Low-Current OCV

The above data files have been referenced in:

[1] State of Charge Estimation of Lithium-Ion Batteries Using the Open-Circuit Voltage at Various Ambient Temperatures.

Yinjiao Xing, Wei He, Michael Pecht and Kwok Leung Tsui, Applied Energy, 113, pp.106-115, 2014.

[2] State of Charge Estimation for Li-Ion Batteries Using Neural Network Modeling and Unscented Kalman Filter-based Error Cancellation.

Wei He, Nicholas Williard, Chaochao Chen, Michael Pecht , International Journal of Electrical Power & Energy Systems, 62, pp.783-791, 2014.

Prismatic Cells

CS2 Battery

| Battery (Parameters) | Specifications (Value) |

| Capacity Rating | 1100 mAh |

| Cell Chemistry | LiCoO2 cathode, EDS results also showed trace elements of Manganese |

| Weight (w/o safety circuit) | 21.1 g |

| Dimensions | 5.4 x 33.6 x 50.6 mm |

| Special Notes | Jellyroll configuration wrapped around the "length" axis, indicated by red arrows below |

Data and Test Description

All CS2 cells underwent the same charging profile which was a standard constant current/constant voltage protocol with a constant current rate of 0.5C until the voltage reached 4.2V and then 4.2V was sustained until the charging current dropped to below 0.05A. Unless specified, the discharge cut off voltage for these batteries was 2.7V. All the CS2 cells were randomly numbered and named accordingly. Name 'CS2_n' was given for the nth numbered CS2 cell.

Each CS2 cell was cycled multiple times under the conditions mentioned adjacent to its name in the table below. The data files for each cell contain a collection of excel files of logged data generated from its testing. These excel files were named according to the testing dates. All cells except CS2_8 and CS2_21 were tested using the Arbin Battery Tester. CS2_8 and CS_21 were tested using CADEX Battery Tester and hence data files for these cells are in .txt format and is available below for download.

Type 1

Cycled at constant current of 0.5C

| Files: |

Type 2

Cycled at constant current of 1C

| Files: |

Type 3

Cycled at constant current discharge, Each cycle the discharge current was alternated between 0.11, 0.22, 0.55, 1.1, 1.65 and 2.2 Amps.

| Files: |

Type 4

Cycled at a constant current discharge of 0.55A. The cut-off voltage was changed at random times to simulate a users uncertain cut-off voltage behavior.

| Files: |

Type 5

For each file, the battery was first fully charged and then fully discharged at 0.22A. Then the battery was cycled between 3.77V and 2.7V with a 0.55A discharge current in order to cycle the battery in a low regime partial charge/discharge cycle.

| Files: |

Type 6

For each file, the battery was first fully charged and then fully discharged at 0.22A. Then the battery was cycled between 4.2V and 3.77V with a 0.55A discharge current in order to cycle the battery in a high regime partial charge/discharge cycle.

| Files: |

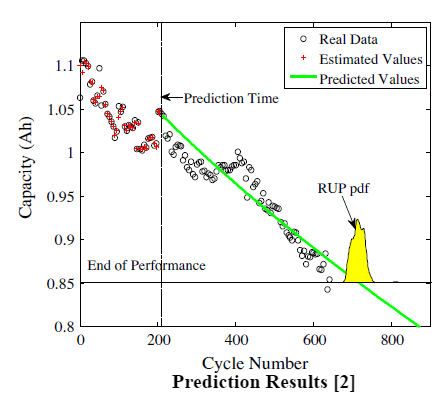

The above data files have been referenced in:

[1] Prognostics of lithium-ion batteries based on Dempster–Shafer theory and the Bayesian Monte Carlo method.

Wei He, Nicholas Williard, Michael Osterman, Michael Pecht, Journal of Power Sources, 196(23), pp.10314-10321, 2011.

[2] An Ensemble Model for Predicting the Remaining Useful Performance of Lithium-ion Batteries.

Yinjiao Xing, Eden Ma, Kwok Leung Tsui, Michael Pecht, Microelectronics Reliability, 53(6), pp.811-820, 2013.

CX2

| Battery Sample | Battery (Parameters) | Specifications (Value) |

|---|---|---|

|

Capacity Rating | 1350mAh |

| Cell Chemistry | LiCoO2 cathode. EDS results also showed trace elements of Manganese | |

| Weight (with safety circuit removed) | 28g | |

| Dimensions (mm) | 6.6 x 33.8 x 50 | |

| CX2 Battery | Special Notes | Jellyroll configuration wrapped around the "width" axis |

Data and Test Description

All CX2 cells underwent the same charging profile which was a standard constant current/constant voltage protocol with a constant current rate of 0.5C until the voltage reached 4.2V and then 4.2V was sustained until the charging current dropped to below 0.05A. Some minor variations were incorporated in this standard charging profile for some of the CX2 cells mentiond below. Unless specified, the discharge cut off voltage for these batteries was 2.7V. All the CX2 cells were randomly numbered and named accordingly. Name 'CX2_n' was given for the nth numbered CX2 cell.

Each CX2 cell was cycled multiple times under the conditions mentioned adjacent to its name in the table below. The data files for each cell contain a collection of excel files of logged data generated from its testing. These excel files were named according to the testing dates. All cells except CX2_4 and CX2_31 were tested using the Arbin Battery Tester. CX2_4 and CX2_31 were tested using CADEX Battery Tester and hence data files for these cells are in .txt format. For the cell CX2_4, which was cycled at different temperatures, thermocouple data is also provided in the Temperature folder of CX2_4 data files. This data is in the .xlsx format and is available below for download.

Cycled at constant current of 0.5C

| Files: |

The above data files have been referenced in:

-

[1] Prognostics of lithium-ion batteries based on Dempster–Shafer theory and the Bayesian Monte Carlo method.

Wei He, Nicholas Williard, Michael Osterman, Michael Pecht, Journal of Power Sources, 196(23), pp.10314-10321, 2011. -

[2] An Ensemble Model for Predicting the Remaining Useful Performance of Lithium-ion Batteries.

Yinjiao Xing, Eden Ma, Kwok Leung Tsui, Michael Pecht, Microelectronics Reliability, 53(6), pp.811-820, 2013.

Pouch Cells

PL Samples

| Battery Sample | Battery (Parameters) | Specifications (Value) |

|---|---|---|

|

Capacity Rating | 1500mAh |

| Cell Chemistry | Graphite/LiCoO2 | |

| Weight (with safety circuit removed) | 30.3gm | |

| PL Samples | Dimensions | 3.4 mm x 84.8 mm x 50.1 mm |

Cyclic Data and Test Description

Lithium-ion batteries are used for energy storage in a wide array of applications, and do not always undergo full charge and discharge cycling. We conducted an experiment which quantifies the effect of partial charge-discharge cycling on Li-ion battery capacity loss by means of cycling tests conducted on graphite/LiCoO2 pouch cells under different state of charge (SOC) ranges and discharge currents. The results are used to develop a model of capacity fade for batteries under full or partial cycling conditions. This experiment demonstrates that all of the variables studied including mean SOC, change in SOC (ΔSOC) and discharge rate have a significant impact on capacity loss rate during the cycling operation. The initial characterization tests for the cells included constant current constant voltage (CCCV) charge - constant current (CC) full discharge (4.2V - 2.7V) at C/2 rate to determine battery discharge capacity. The test procedure is as follows:

- Cells were initially charged to 100% SOC using the CCCV profile at C/2 rate.

- After reaching 100% SOC, the cells were discharged using constant C/2 current until they reached the lower limits of their assigned SOC ranges (i.e., 20% for 20% - 80% range) for partial cycling.

- Constant current charge (always C/2) and constant current discharge (C/2 or 2C) were applied to the cells for cycling between the desired upper and lower limits of SOC (i.e., 20% - 80%).

- A rest period of 30 min was applied to allow the cells to relax after every charge and discharge steps.

The results highlighted that the graphite/LiCoO2 battery degradation is affected by mean SOC as well as the change in SOC (ΔSOC) during the cycling operation. (Coulomb counting method has been used to calculate the time durations of charge and discharge to maintain the SOC values within designated SOC ranges).The data from the experiment is available for download below:

The above data files have been referenced in:

-

[1] Cycle Life Testing and Modeling of Graphite/ LiCoO2 cells under different state of charge ranges.

Saurabh Saxena, Christopher Hendricks and Michael Pecht, Journal of Power Sources, 327 (2016), pp.394-400, 2016.

Storage Data and Test Description

A total of 144 Li-ion cells with three different SOC values (0% SOC, 50% SOC and 100% SOC) underwent battery storage life test under four different temperatures (-40C, -5C, 25C, 50C).

- 12 cells were stored at each of these temperatures: -40C, -5C, 25C and 50C.

- Of the12 cells stored at each temperature, 4 cells were stored at 50% SOC, 4 cells at 100% SOC, and 4 cells at 0% SOC.

- 48 cells underwent capacity testing and impedance measurement every 3 weeks; 48 cells underwent capacity testing and impedance measurement every 3 months; and 48 cells underwent capacity testing every 6 months.

For example: Cell PLN_51 underwent the initial capacity test with CCCV charging at a rate of C/2. Once the current fell below C/100 rate, the cell was discharged at a rate of C/2 to accumulate the deliverable maximum capacity of the cell. Then, the cell was fully charged using the same CCCV profile followed an impedance test. In the next step, the cell was discharged to 50% SOC through calculating the accumulative capacity to half of the maximum capacity. Further, the cell was stored into the temperature chamber for 3 weeks. After 3 weeks, the cell would be taken out for the capacity and impedance tests.

Other Cells

K2

Battery Sample |

Battery (Parameters) |

Specifications (Value) |

|---|---|---|

|

|

Capacity Rating |

2600mAh |

Cell Chemistry |

LiFePO4 |

|

Weight (with safety circuit removed) |

80.5g |

|

Diameter |

26.5 mm +-0.2mm |

|

Length |

65.2 mm +-0.4mm |

|

Nominal Voltage |

3.2 V |

|

Cycle Life |

2000+ |

|

K2 Battery |

Special Notes |

Tab length is not included in the dimensions. |

Data and Test Description

The K2 battery test for K2-016 and K2-039 is descibed as follows:

-

Discharge the battery for constant current at 2.6A

-

Discharge until voltage is 4.2V

-

Charge at constant voltage until current < 0.08A

-

Rest for 2 minutes and measure the resistance

-

Rest for 1 minute.

K2-016: |

|

K2-039: |

|

Notice

Top