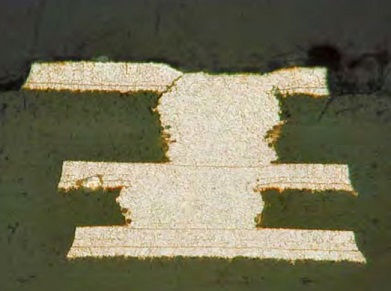

Defect Description

Cracks initiated at the junctions between the microvia corner and the capture pad that are prone to propagation upon the exposure to environmental stresses [1].

Defect Formation Process(s)

The cracks are often present in products that experience an overly aggressive copper removal operation (planarization), resulting in very thin pads, usually only copper foil remains, with all microvia electrolytic copper plating being removed [1].

|

List of Tests to Precipitate this Defect |

Failure Acceleration |

Likihood to Precipitate Defect (condition) |

Failure Mechanism(s) |

|

Thermal Shock |

• Cyclic thermal mechanical stress accelerates crack growth due to the local stress concentration • Thermal mechanical stress causes fracture of the microvia at the cracks where local stress concentration is high |

✔ |

Thermal Fatigue Thermal Mechanical Overstress |

|

Random Vibration (RS/ED) |

• Random Vibration accelerates crack growth due to the local stress concentration • Vibration causes fracture of the microvia at the cracks where local stress concentration is high |

✔/✇ |

Mechanical Fatigue Mechanical Overstress |

|

Combined Environment |

• Combination of Thermal Shock and Random Vibration |

✔ |

Combination of Thermal Shock and Random Vibration |

|

Bend Test |

• Bending can cause fracture of the copper plating at the cracks where local stress concentration is high |

✇ (Defect at a location with significant strain due to bending) |

Mechanical Overstress |

[2]

[2]

References

Permission for pictures

[2] Ghaffarian R. “Reliability of PWB Microvias for High Density Package Assembly”, NASA Electronic Parts and Packaging Program (NEPP), 2006.

Top