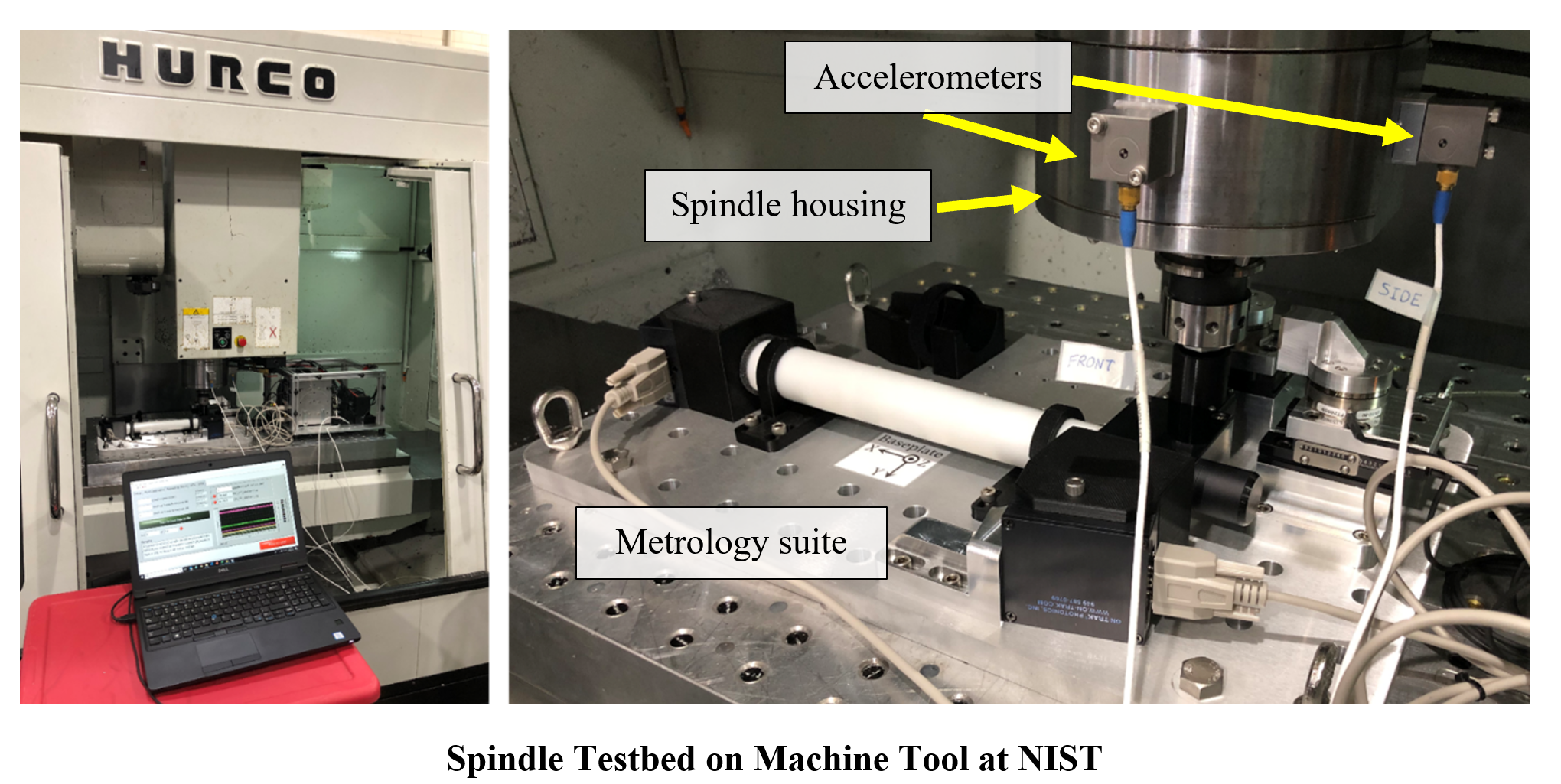

Machine tools are essential for production in manufacturing facilities. Unplanned downtime caused by machine tool failures and the degradation of performance of machine tools impact productivity, leading to lost profit and market opportunities. Although some methods exist to track the performance of machine tools, they are costly and time-consuming because they evaluate the performance offline and require special equipment. The National Institute of Standards and Technology (NIST) and CALCE are developing a novel in-situ performance measurement method for machine tools. Dr. Gregory Vogl is a task leader within the “Monitoring, Diagnostics, and Prognostics for Manufacturing Operations” project at NIST and has developed a testbed for prognostics and health management of machine tool spindles and cutting processes. The testbed is equipped with accelerometers as well as gyroscopes, force, and torque sensors, and laser spot position sensors (the “metrology suite”) to characterize machine tools. Through the NIST Professional Research Experience Program (PREP), Dr. Michael Azarian and Mr. Nam Kyoung Lee from CALCE have been supporting the project to develop an algorithm to characterize machine tools using the sensor data. Mr. Lee is modeling the non-linear relationship between acceleration and force measured from the testbed by using deep learning. His model will contribute to estimating machining forces and spindle speeds, by relying solely on accelerometer signals. This will simplify condition monitoring and enable real-time health management and asset optimization with low-cost and readily available sensors.

For more information on this and other topics related to the applications of prognostics, contact Dr. Michael Azarian.

Top