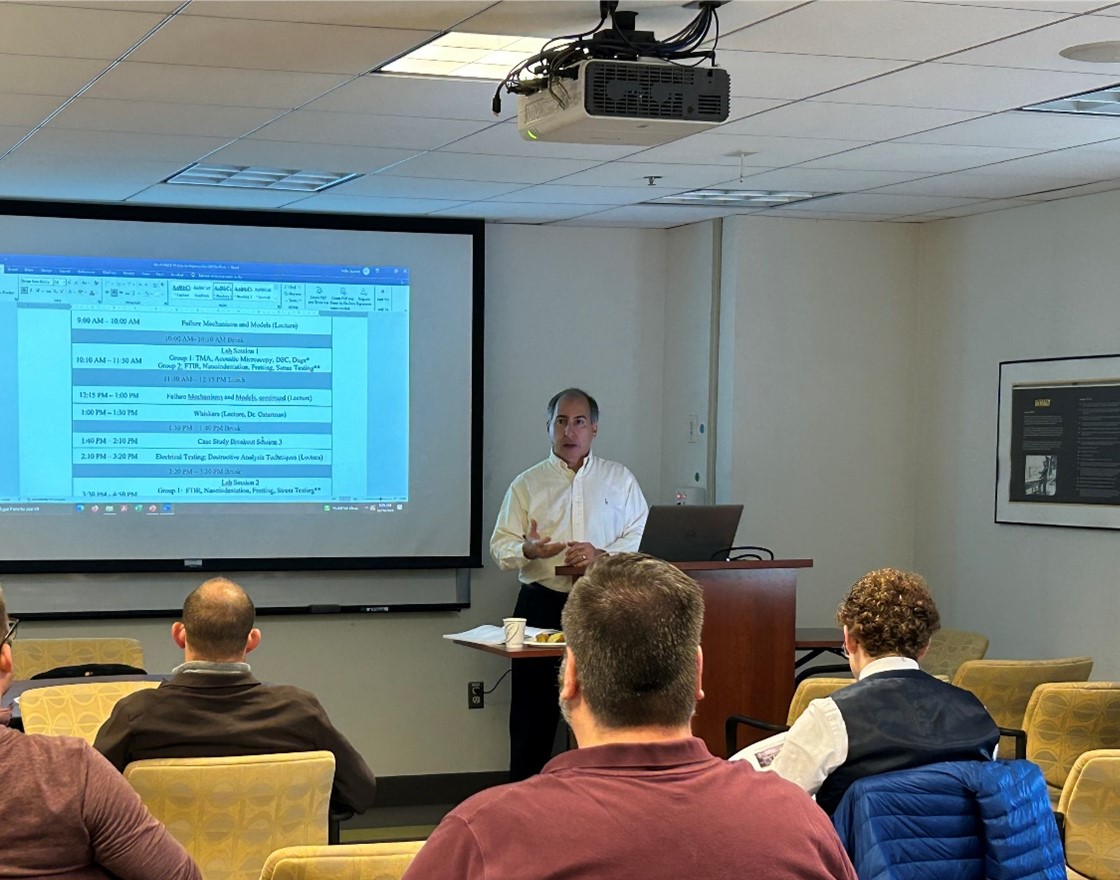

Starting Tuesday, November 14, this four-day annual failure analysis was held at CALCE. The course covered why electronics fail, how to set up specimens, the science behind failures, reliability, ways to determine the root cause, and methods for looking into materials. Practicing engineers and analysis from the industry and governments attended this limited enrollment course. Scientists and engineers participated from organizations like Danfoss Drives, VPT Inc., Air Force, Magic Leap, Ford Motor Company, Qorvo, University of Dayton Research Institute (UDRI), S&C Electric, Embraer, and Ford Motor Company. For those interested in future failure analysis courses, please reach out to Dr. Michael Osterman and Dr. Michael H. Azarian.

This 4-day program focused on preparation and materials analysis techniques applicable to electronic assemblies, components, and devices. The course structure incorporated a blend of classroom instruction, demonstrations, and hands-on laboratory training. Lecture topics encompassed physics-of-failure root cause analysis, guidelines for selecting analytical tools, practical instruction on laboratory techniques, and case studies derived from CALCE’s research. The laboratory segment featured step-by-step, hands-on sample preparation using metallographic techniques on failure analysis and inspection equipment. Additionally, numerous crucial non-destructive and destructive analysis techniques were showcased.

Delving deep into the root cause failure analysis of electronic components is both exciting and demands vigilance, dedication, and a profound understanding of current industrial advancements. This comprehensive exploration equips professionals with invaluable insights crucial for addressing challenges and driving innovation in the rapidly evolving field of electronic component analysis.

For more courses, visit CALCE professional development courses.

Top