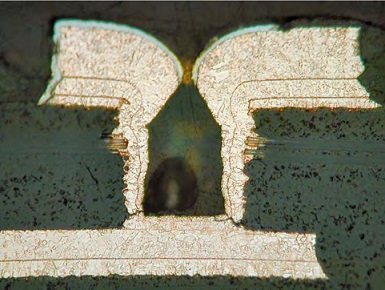

Defect Description

Barrel cracks are usually found with a taper towards the base of a microvia that are prone to propagation upon the exposure to environmental stresses.

Defect Formation Process(s)

Main cause for most plating problems are related to a dysfunctional combination of chemistry and equipment. It is found that PWB manufacturers use different suppliers for various chemical components within the metallization line; this can create chemical incompatibilities between critical preparation steps (cleaning, desmearing, micro-etching, glass-fibre etching, conditioning, activation, etc.)

|

List of Tests to Precipitate this Defect |

Failure Acceleration |

Likihood to Precipitate Defect (condition) |

Failure Mechanism(s) |

|

Thermal Shock |

• Cyclic thermal mechanical stress accelerates crack growth due to the local stress concentration • Thermal mechanical stress causes fracture of the copper plating at the cracks where local stress concentration is high |

✔ |

Thermal Fatigue Thermal Mechanical Overstress |

|

Random Vibration (RS/ED) |

• Random Vibration accelerates crack growth due to the local stress concentration • Vibration causes fracture of the copper plating at the cracks where local stress concentration is high |

✔/✇ |

Mechanical Fatigue Mechanical Overstress |

|

Combined Environment |

• Combination of Thermal Shock and Random Vibration |

✔ |

Combination of Thermal Shock and Random Vibration |

|

Bend Test |

• Bending can cause fracture of the copper plating at the cracks where local stress concentration is high |

✇ (Defect at a location with significant strain due to bending) |

Mechanical Overstress |

References

Top